Where We Add the Most Value

We support your fab and equipment with a mix of hands-on engineering and smart software. From on-tool performance to robust SPC dashboards, these three pillars are how we help teams move faster with fewer surprises.

Tool Optimization

On-tool performance,

equipment health,

monitoring, and uptime.

Process Support

Process development,

yield improvement,

and SEM-driven feedback.

Software Solutions

SPC dashboards,

drift/health monitoring,

data collection & automation.

Why JJP Technology

Industries & Applications

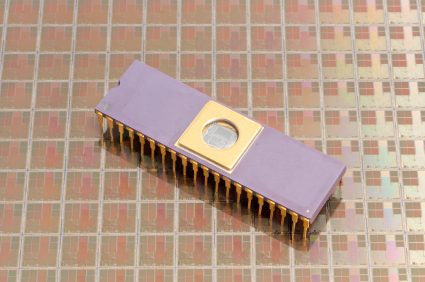

Semiconductors

Process tuning,

yield recovery, and equipment

performance for wafer fabs.

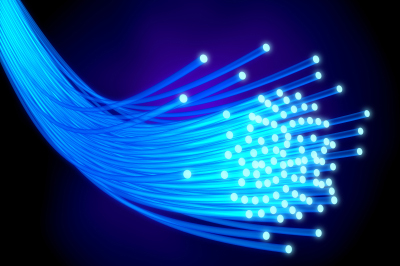

Photonics & Optoelectronics

Thin-film control,

device uniformity, and precision

alignment for optics lines.

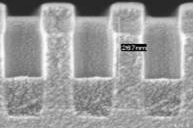

MEMS & Sensors

Critical dimension,

etch profile, and release-step

optimization for MEMS.

Energy Storage & Batteries

Electrode and coating

uniformity, defect reduction,

and cell performance.

Etching & Thin-Film

Recipe development,

chamber matching, SPC, and

metrology feedback for films.

Coating Applications

PVD/CVD optimization,

adhesion control, and surface

properties for coatings.

What We Do

We help fabs, equipment makers, and materials companies improve yield, stability, and productivity through practical engineering and data-driven tools. Backed by decades of semiconductor expertise and a trusted network of engineers, we provide solutions that improve yield and manufacturing performance.

How We Work

Start small

Test us on a focused

task or pilot project.

Collaborate

Weekly checkpoints, clear

deliverables, and transparent data.

Scale

Extend the scope only

when we’re clearly adding value.

Recent Focus

-

Stabilizing etch and clean steps to unlock yield in production lines.

-

Independent RF source and OES evaluations to support new tool launches.

-

Fast SPC rollout to visualize drift and excursions in the pilot line.

.

Experience at a Glance

We’re a small, specialized team with big-company experience and a focused network of experts.

About our Company

JJP Technology LLC helps high-tech manufacturers stabilize processes, improve yield, and monitor equipment health. Led by Carmine Federico (28+ years across fabs, tool vendors, and R&D), we combine real fab experience, SEM-driven insight, and practical SPC/DOE discipline to solve daily production problems.

Practical Solutions for Fabs, OEMs, and R&D Labs

At JJP Technology LLC, we help semiconductor fabs, equipment manufacturers, and high-tech startups solve real production problems. Drawing on decades of hands-on experience in process development, etch and deposition, SPC, and equipment health monitoring, we work side-by-side with your team to stabilize processes, improve yield, and standardize best practices. Whether you need support for a new tool install, a difficult process window, or data-driven SPC and monitoring software, we provide practical, actionable solutions that fit your factory and your timeline.

We Help Businesses

To Achieve Their Goals

We partner with semiconductor fabs, equipment makers, and high-tech startups that need experienced, hands-on support rather than generic consulting slides. Whether it’s a difficult etch step, a new tool launch, or a quick SPC rollout, we focus on clear results, documented know-how, and solutions your engineers can actually run tomorrow.

Our Vision

After decades working inside major corporations and R&D labs, we’ve seen what works — and what slows teams down. Our vision is to make that experience available to companies of any size, giving them the same level of process rigor, equipment insight, and data discipline that large fabs expect.

Experience at the Heart of What We Do

JJP Technology was built to bridge the gap between big-company expertise and the realities of smaller teams and growing fabs. We bring senior-level knowledge without the overhead, working alongside your engineers to transfer skills, methods, and tools so your organization keeps the benefits long after a project ends.

Current Activities